CFA vs Rotary Bored Piling; Which method should you choose?

Piling, by definition, is the process of strengthening or supporting a structure. Piling is often considered as foundations which are driven or bored into the ground at specific points to help transfer loads within soil and increase the load capacity of a structure. At present, there are a variety of specialist piling techniques available to contractors. Determining which method is needed will depend on a range of factors, such as ground conditions, soil type, and project characteristics like the type of structure being built.

CFA and rotary bored piling are two of the most commonly adopted drilling techniques. We’ve put together a quick comparison to see the potential advantages and disadvantages, as well as the usability criteria of both methods, to better understand when and where to use each method.

CFA Piling

Continuous flight auger (CFA) piling is a commonly used, and highly versatile, method of installing foundations in a wide range of conditions. Quick, quiet, and virtually vibration-free, this popular technique is best suited to urban projects or environmentally sensitive surroundings. Suitable for installation in the majority of soil conditions, including dense sand, clay and low-grade rock, CFA piles are able to be utilised in a range of environments and construction projects. Ideal for urban locations, CFA piling is an effective solution when it comes to working close to existing structures or in built up areas due to the minimal vibrations, disturbance caused to adjacent buildings, and overall noise pollution.

There are many advantages associated with CFA piling. From the broad range of auger sizes and depths of around 25m achieved, to the efficient and cost-effective way of working, utilising the CFA method enables work to be completed on a broad range of sites and projects within a condensed time scale. A downside to CFA piles is that although they are ideal for a large number of projects, this method may not be adequate for very soft clay, silt-based soil or any other loose topography including sand and gravel. However, generally speaking, CFA piling is a versatile technique suitable for an assortment of locations, projects, and ground conditions.

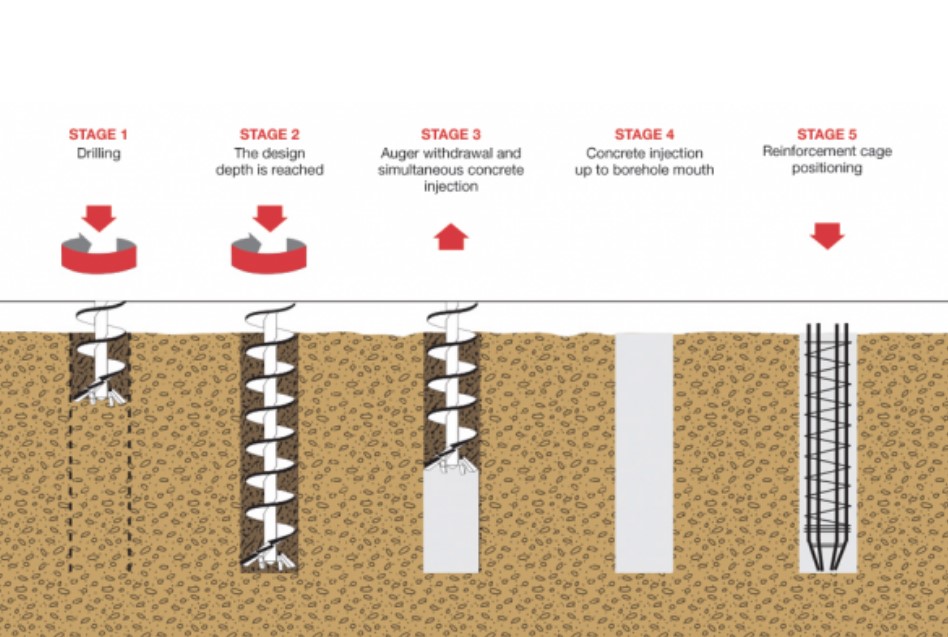

So how does it work? CFA piles are installed using a continuous hollow stemmed helical auger which is rotated into the ground by the piling rig. Once the desired depth has been reached, concrete is pumped through the auger as it is slowly extracted. During the extraction process, excess soil and pile arising are cleared using an auger cleaner. Immediately after the auger is extracted, a reinforcement cage is inserted into the concrete to provide additional support and stability.

Rotary Bored Piling

Rotary bored piles are used across a broad range of sectors within the construction industry. From large scale commercial developments and infrastructure schemes like HS2, to retaining walls and marine projects. Bored piles are often larger in diameter than conventional CFA piles and are used to support larger loads. Rotary piling is a commonly used method, conducted using larger rigs which offer higher torque, enabling them to penetrate harder ground and overcome underground obstructions or challenges. Piles are installed using specifically designed digging tools which are able to reach excessive depths and diameters. This technique is suitable for use in almost all soil conditions and allows contractors to facilitate top-down construction. When compared to other foundation methods, bored piling offers a higher load capacity and can be deployed at a much greater width and depth.

Like CFA piling, the rotary bored technique also has many advantages and uses within construction. Bored piling is able to be utilised in a variety of ground conditions, from soft ground to rock drilling, with operators achieving depths of up to 60m and a diameter of up to 1.8m. Additionally, this technique ensures minimal ground disturbance, ground heave, and vibrations due to the support provided by the casing. Rotary piles have a simple and efficient installation process and are able to be used successfully across a range of projects. However, due to the size and volumes of materials being used, significant spoils are often generated which need to be handled correctly. Additionally, rotary piling often requires more workers and the coordination of multiple trades.

So how does it work? The rotary piling technique uses prefabricated bored piles that are inserted into the ground to support the weight of the structure being built on top. Bored piles are constructed by using a powerful hydraulic piling rig, a telescopic Kelly bar, and a variety of interchangeable digging tools. An encasing is rotated into the ground, upon reaching the desired depth the pile bore is then extracted using an auger, bucket, or coring unit connected to the Kelly bar. Once the bore is fully cleaned, concrete is tremmied into the bore with the casing being extracted, resulting in a complete pile.

To conclude, both piling methods discussed above have their own pros and cons, but ultimately are two useful techniques suited to a wide range of projects and sites. Did you know, we have a wide range of piling rigs capable of working in both CFA and rotary configuration? Available for nationwide hire and/or international purchase, we have a selection of piling rigs and drilling equipment suitable for all types of projects and sites. Contact our team today to learn more.